TRY TO COMPLETE THE 13 QUESTIONS BELOW IN LESS THAN 20 MINUTES. NOTE THAT THE ACTUAL EXAM CONTAINS 100 QUESTIONS (for Green Belt), 150 QUESTIONS (for Black Belt) AND MUST BE COMPLETED AS A CLOSED-BOOK EXAM WITHIN 2 HOURS (for Green Belt), or 3 HOURS (for Black Belt). So that you can manage your total project period.EXAMPLE ILSSI, CSSC SIX SIGMA CERTIFICATION GREEN In the project plan section, you should take the target date of all 5 phases and monitor the actual date and delay of project.

Intangible benefits: For example, Increase Customer Satisfaction, Knowledge about 6-Sigma tools, Improved Presentation skill, improved analytical Knowledge, Improved team work & self, Problem Solving Skill developed. 1.1% to 0.02%, DPPM from 11300 to 150, DPMO from 1800 to 25, and for example estimated cost saving 50 lakhs/annum. Tangible Benefits: Improvement of sigma level e.g. For example, Process P-1 is included and process p-2 is excluded. Here, you just mention the project boundary like what is included and what is excluded. or To reduce the rejection PPP by 90% from x to y. Mainly describe the project objectives & goal like to reduce the rejection% from x% to y%. How much: you can mention here rejection in percentage or in PPM or in DPMO. When: during manufacturing of parts in three shifts

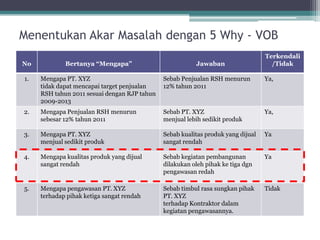

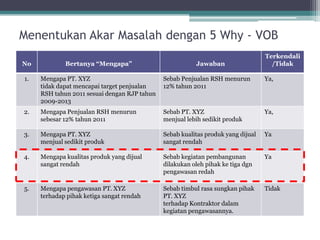

We have used the 5W2H template to describe the problem statement.Īs you know, there is high process rejection of Part-1 at process P-1.

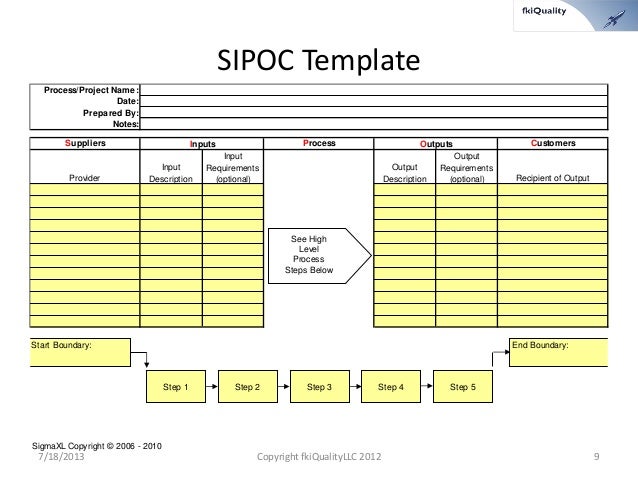

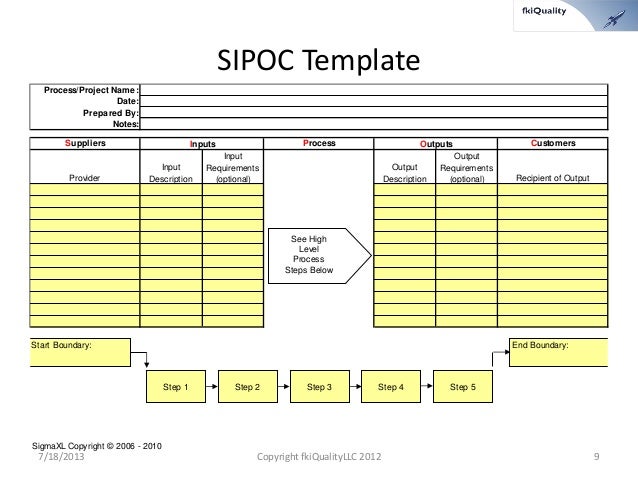

Define the scope, project goal, estimated benefits and project objectives.įirst of all, try to form a six sigma team and define their project roles & responsibility, once you done the same next write the problem statement, same we are going to write here considering with the above example. Next part is the Problem statement, here you can write the statement by using the 5W1H or 5W2H template. For the knowing the defects contribution you can use the Pareto chart. After calculating the DPMO value, then easily from six sigma conversion table you can find the sigma level. You can manually calculate the DPMO or you can use the DPMO Calculator as well.

for better result and considering with all environmental impact you can consider 12 months to 18 months data.

Minimum, Keep the past 3 to 6 months data for calculation of sigma level, DPMO, and defects contribution. Form a Six sigma team including designation, and roles & responsibility of all members. For reducing the high rejection percentage at process P-1, the six- sigma certified holder has taken a project on it and prepared the project charter.įollow the below steps to prepare the six-sigma project charter: At process P-1, they are manufacturing Part-1. Let’s consider an example here for preparing the six-sigma project charter, for doing so we are going to consider here an example of the manufacturing industry for better understanding, suppose the manufacturing unit is producing automobile parts and somehow rejection% at process P-1 is high.

After getting the approval from concern personnel, you can start your project. Which is consist with some basic information about project, problem statement, scope, goal, tangible and intangible benefits, team members, and final the approval part. The Six sigma project charter is the main part of the any type of 6-sigma project.

#Six sigma green belt project report examples how to#

Six Sigma Project Examples How to write six sigma project charter? Process and Product failure improvement project.Six sigma projects on customer complaint.Breakdown time, MTTR and MTTBF improvement project.Waste reduction and production optimization.Define phase, Measure phase, analyze phase, improve phase and control phase.įollowing are some example of six sigma project that you can consider to do but there are not limited to.Follow the six-sigma methodology like DMAIC.Once you finalize the number of projects as per prioritize my six-sigma committee and top management, you can prepare the six-sigma project charter. Categories the problems like A types, B types, C types and K types.Īfter categorization of problems you can select the C type problem for six sigma projects.Identify the current problems or issues, like defects issue, high process or product characteristics variation, high rejection, high warranty issue, customer complaint, high break down, reduction of energy consumption, cycle time reduction, lead time reduction, etc.

0 kommentar(er)

0 kommentar(er)